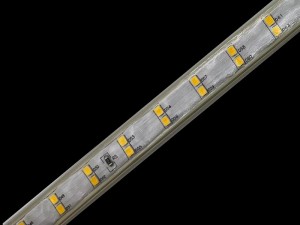

SMD LED Flexible Strip SMD2835 LED STRIP LIGHT(12V/24V)

Features

Flexible PCB board, various of waterproof types for different environments;

5 merters per reel, cuttable by specified length;

Easy to install and maintain, Wide applicability;

Extremely Brightness, with 120 degree viewing angle;

Energy saving and environmental conservation, long life span;

Operation low voltage (DC12V/DC24V) for human safety, various colors available.

Application

Indoor and outdoor decorative lighting for hotel, advertising light box, KTV, etc;

Landscape outlines,residential or public facilities;

Advertising Signs, light boxes;

LED Linear Lighting;

Emergency hallway lighting;

Architectural decorative lighting;

Building contour decorative lighting;

Linear LED Fixture; LED Retail Lighting;

Car and motorcycle decorative lighting;

Large scale back light Window display lighting;

Cabinet LED Lighting; Showcase LED Lighting; LED Museum Lighting;

LED Kitchen Lighting; Display LED Lighting; Art LED Lighting;

Holiday decorative lights, display and exhibition lighting;

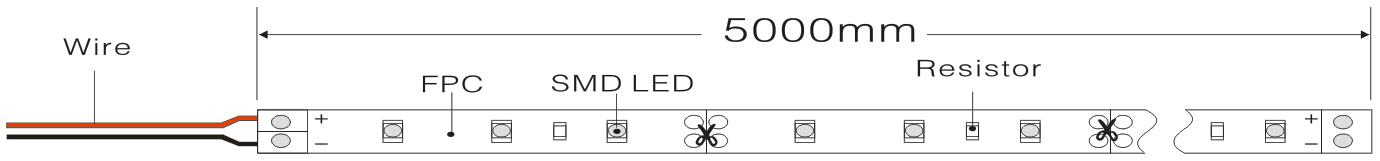

Dimension

Parameter

| LED type | 2835 | |||

| Part No. | HXD2835-60 | HXD2835-120 | HXD2835-180 | HXD2835-240 |

| Voltage | 12/24V | |||

| LEDs/m | 60 | 120 | 180 | 240 |

| Watts/m | ≤4.8W/M | ≤9.6W/M | ≤14.4W/M | ≤19.2W/M |

| Run Length | 5/10meters/roll | |||

| CCT | WW/NW/CW/Red/Green/Blue/Yellow/Golden/Purple/Orange | |||

| IP Rating | IP20/IP65/IP68 | |||

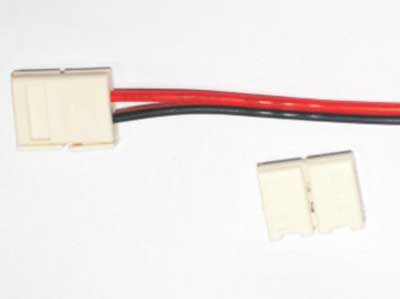

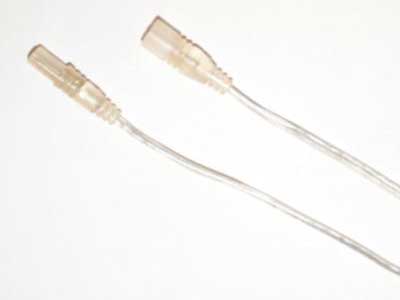

Accessories

Waterproof DC connectors

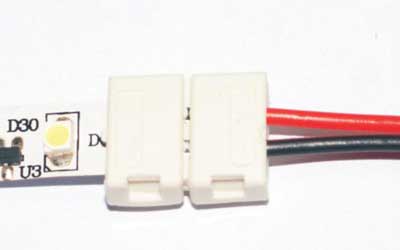

Connectors( for non-waterproof strip)

wire waterproof connector

Silicon clips IP65

Silicon clips IP20

End cap

Operation guidance(Non-waterproof)

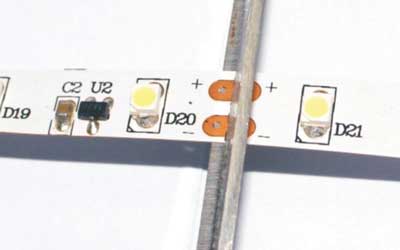

1.Cut the light strips at the mark“scissors”

2.Put the PCB in the space between clip and connector,make the clips exactly aim at welding point

3. Close the cover of connector

4.Put the PCB in the space between clip and connector,make the both clips exactly aim at welding point

5.Close the cover of connector

Operation guidance (Waterproof)

- Cut the light strips at the mark" scissors".or by every 3 leds

- Open the siliconglue cap and inject the silicon gel into the endcap without holes

- Push the strips into the end cap and let the silicon gel dry for 1 hour

- Put the connector wire through the end cap holes

- Solder the wire on the PCB

- After solder the two wires correctly,push the strips into the end cap with the wires carefully

- Inject the silicon gel in the end cap

- Make sure the end cap and strip are connected well and let silicon gel dry for 1 hour

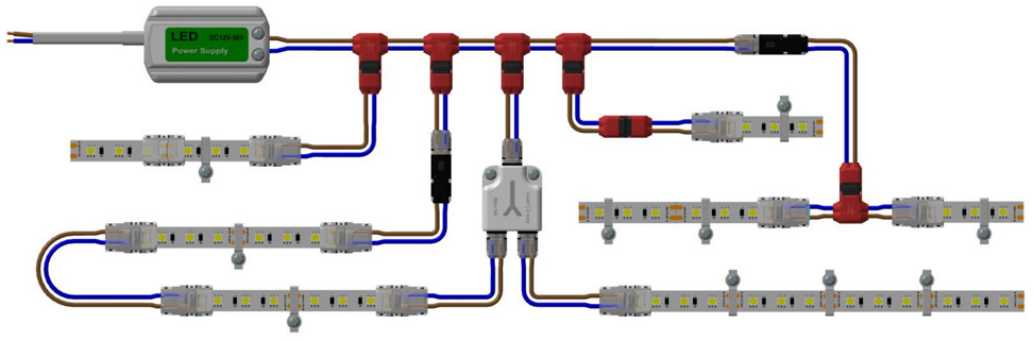

Connection Drawing

power supply

Note: Under use, the suggestion for the power would be 20% bigger than LED strip's Max power to insure the uniformity of the brightness and long time good performance of power supply.

Note

1.Please apply different IP rate products according to different environmental conditions;

2.Notice no damage to the PCB's circuit under installation;

3.Adopt suitable power supply to match the led strips. Power is 20% bigger than max.power of led strips to ensure the long time performance of power supply;

4.Forbid to install it when power on. before power on ,please make sure that wiring is correct once installation finished;

5.In order to get the best lighting effect and no damage. Max.continuous length is 15 meters;

6.Please do not stare at the light for a long time when it is working to protect your eyes;

7.Only professional personnel may dismantle and repair.